Category

Professional Cars Lens Plastic Mold and Truck Lamp Injection Mould

Taizhou ANO Mould CO.,ltd,20 years professor in Auto part molds,lens mold,fog lamp mold,bumper molds and so on.35 mold m

Basic Info.

| Application | Car |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 3years |

| Transport Package | Wood Case, Standard Carton, Pallet or Customized |

| Trademark | ANO |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 500/Set/Year |

Product Description

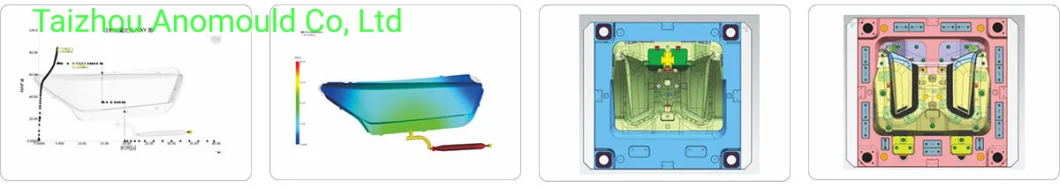

Taizhou ANO Mould CO.,ltd,20 years professor in Auto part molds,lens mold,fog lamp mold,bumper molds and so on.35 mold maker(15 years),5 engineers(20 years),1 QC 15 years,5 designer(UG,CAD). Customer from Europe, North America ,South America,Taiwan,Iran,Ukraine.Honest quality,honest service,we are waiting our cooperation,you will satisfied in ANO mould.Professional Cars Lens Plastic Mold and Truck Lamp Injection Mould

Our principle is:1.Refuse to built poor quality mold to get profit.2.Honest mold! Honest price! Honest service!Please contact with us to get best Crate mold suggestion and satisfaction!Our Mold flow:A:Check samples or drawings from customer.B.Complete molds design,and start mold building after mold drawing confirmed.C.1st test mold,and send samples to customer to confirm.D.Modify the mold according to customer's feed back on 1st testing samples.E.After sample confirmed,package the mold,arrange mold shipped.As soon as mold job start,we will provide time plan,and inform custom 1st testing time.Every Monday,provide weekly report contains weekly photos.

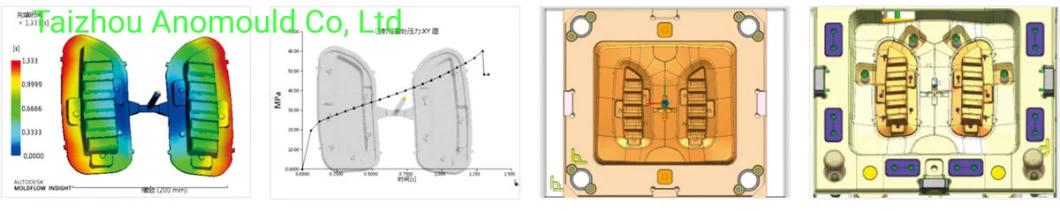

DFM

Design for Manufacturing or Design for Manufacturability (DFM) is the optimization of a part, product, or component's design, to create it cheaper and more easily. DFM involves efficiently designing or engineering an object, generally during the product design stage, when it is easier and less expensive to do so, to reduce manufacturing costs. This allows a manufacturer to identify and prevent mistakes or discrepancies.

Advantages of DFM:

*Products made with DFM will have a lower production cost

*Quicker time-to-market

*Shortening of the product development process

*Production will be up to speed sooner

*Parts may be combined to reduce assembly steps and quantity of parts

*Catches and removes mistakes or faults

*Higher quality of a product, as design can be refined and enhanced at every stageQ. Are you manufacture?

A: Yes, we are plastic injection mould manufacture

Q. I have no 3D drawing, how should I start the new project?

A: We very welcome you give us the samples, we will help you finish the 3D drawing design.

Q: I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A: Yes! We are always happy to work with customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: How to make sure the quality before the shipment?

A: will send the mould tooling schedule, mould pictures and processing report to buyer each 10 days. After mould fiished we will do the testing to make sure the mould is work well, we will send all testing picture and video to customer.

Q: How to send sample?

A:The quotation we offer to you including the cost of sample delivery 1-2 times. We send sample by DHL, UPS, EMS ,FEDEX or TNT.

Welcome to send inquiry!

Previous: Customized PP POM ABS Computer Parts Industrial Tablet Shell Enclosure Dual Injection 2K Molding Overmold Insert Mold Plastic Injection Mold OEM

Next: Custom Made Mould Base Frame Plate High Precision Tooling Maker Plastic Injection Mould for Auto Part Home Appliance Medical instrument Structure Parts

Send inquiry

Send